Complete Guide to Veterinary Surgical Instruments: Types, Uses, and Categories

Complete Guide to Veterinary Surgical Instruments: Types, Uses, and Categories for Veterinary Professionals

Veterinary surgical instruments are the specialized tools used to perform diagnostic, therapeutic, and surgical procedures across species, and understanding their types and applications is essential for safe, efficient practice. This guide explains instrument categories, functional mechanics, specialty sets for dental, orthopedic, and ophthalmic work, and practical selection and maintenance strategies to help veterinary teams choose and care for the right tools. Readers will learn how cutting, grasping, retracting, suturing, and specialty instruments differ, when to use specific blades or scissors, and how sterilization and inspection protocols extend instrument life. The article maps instrument families to clinical examples such as spays, mass removals, fracture repairs, and equine dentistry, and it includes quick-reference tables and checklists to support purchasing and workflow decisions. By the end, clinicians and practice managers will have actionable criteria for procurement, routine care, and integrating modern trends like electrosurgery and minimally invasive options into their surgical repertoire.

What are the main categories of veterinary surgical instruments?

Veterinary surgical instruments group into functional categories that define their primary role in a procedure: cutting, grasping/holding, retracting, suturing, and specialized instruments. Each category reflects a design optimized for a mechanical task—sharp edges for cutting, serrated jaws for secure holding, and shaped blades or frames for exposure—so selecting by function improves precision and safety. Understanding these categories helps teams assemble procedure-specific trays and anticipate complementary instruments needed during surgery. The following list gives concise definitions and one-line examples to aid quick identification and setup.

- Cutting instruments are designed to incise or excise tissue and bone, such as scalpels and bone rongeurs.

- Grasping and holding instruments secure tissue, vessels, or prostheses; examples include hemostats and needle holders.

- Retractors expose the operative field by holding tissue aside, like Gelpi or Balfour retractors.

- Suturing instruments facilitate ligation and suture handling, including needle holders and suture scissors.

- Specialized instruments serve niche procedures—dental floats, orthopedic saws, or ophthalmic microsurgical tools.

These categories often overlap in practice—for example, scissors can function as cutting or dissecting tools depending on blade design—so recognizing functional nuances prepares teams for intraoperative decisions. Knowing how categories interrelate leads into the specifics of cutting and grasping instruments commonly used in veterinary surgery.

Which instruments are classified as cutting tools in veterinary surgery?

Cutting instruments enable precise incisions and tissue or bone removal by combining a sharp edge with ergonomic handles; scalpels, scissors, osteotomes, and rongeurs are primary examples. Scalpel blades vary by number—#10 and #15 are common for general incision and fine work respectively—and the handle-blade system allows quick blade changes and secure control during incisions. Scissors like Mayo are built for heavy tissue cutting while Metzenbaum scissors have fine blades for delicate dissection; bone-cutting tools such as osteotomes and rongeurs remove or contour bone under controlled force. Choosing the right cutting tool depends on tissue density, access, and animal size, and that decision directly impacts wound healing and procedural efficiency.

These cutting tool choices set up the next essential group of instruments: grasping and holding devices that secure tissue or control bleeding during and after incisions, which we discuss next.

What are the key grasping and holding instruments used in veterinary procedures?

Grasping and holding instruments include hemostatic forceps, tissue forceps, towel clamps, and needle holders, each engineered to control tissue or suture materials while minimizing trauma. Hemostats (e.g., Kelly, Crile, Halsted) apply locking ratchets to occlude vessels and control bleeding, whereas tissue forceps (such as Adson or Debakey styles) provide atraumatic or toothed tips for secure grip during manipulation. Needle holders often incorporate tungsten carbide inserts to improve jaw durability and suture control, and towel clamps stabilize drapes and retract soft tissue during prep. Selecting atraumatic tips for delicate organs and toothed tips for denser tissue reduces intraoperative damage and supports precise suturing.

Understanding grasping mechanics leads directly to instrument function mapping across surgical tasks, which clarifies when each holding instrument is most appropriate within common procedures.

How do different veterinary surgical instruments function and what are their specific uses?

Different instrument families function through mechanics matched to surgical tasks: cutting creates incisions, grasping secures tissue, retracting exposes fields, and suturing recreates continuity. Mechanically, cutting tools convert manual force into sharp shearing action; grasping tools use jaw geometry and locking mechanisms to maintain tension; retractors provide leverage or spring action for exposure; and suturing tools enable precise needle control and knot security. Each function maps to common veterinary cases—scalpels and scissors for soft tissue surgery like spays, bone-cutters and rongeurs for fracture repair, and specialized dental instruments for extractions. The following table offers a quick reference mapping instrument → function → typical veterinary applications to guide tray preparation and intraoperative selection.

| Instrument | Primary Function | Typical Veterinary Applications |

|---|---|---|

| Scalpel (e.g., #10, #15) | Incision and precise soft-tissue cutting | Spays, mass excision, skin incisions in small and large animals |

| Mayo scissors | Heavy tissue cutting and suture removal | Abdominal wall closure, fascia cutting |

| Metzenbaum scissors | Fine tissue dissection | Vascular dissection, delicate organ surgery |

| Hemostatic forceps (Kelly, Crile) | Vessel occlusion and hemostasis | Ligation during spay/neuter, tumor excision |

| Needle holder (tungsten carbide) | Suture handling and knot tying | All suturing tasks across specialties |

| Rongeurs / bone cutters | Bone resection and shaping | Orthopedic repairs, dental extractions in equine and canine cases |

This quick reference clarifies how instrument mechanics translate into clinical use and helps teams anticipate complementary tools needed during an operation. For clinicians assembling specialty trays or replacing worn instruments, it is useful to consult reputable suppliers that categorize veterinary instruments by animal type and specialty to match procedural needs.

Vettrix Supplies offers a comprehensive catalog categorized by animal type (Equine, Large Animal, Small Animal) and instrument type (Dental, Orthopedic, Surgical, Ophthalmic, Electrosurgical), which can help practices identify example kits and specialty sets aligned with the functional mappings above. Their emphasis on precision and durability makes it practical to compare instrument families and assemble procedure-specific trays tailored to clinic caseloads.

What are the types and uses of veterinary scalpels and blades?

Scalpels consist of reusable handles and a variety of blade shapes and sizes; common blades include #10 for general incisions, #11 for stab incisions, and #15 for fine, controlled cuts. Blade material and disposal protocols vary—disposable blades reduce cross-contamination risk while reusable handles paired with replaceable sterile blades combine economy with control. In veterinary settings, blade selection depends on animal size and procedure: larger animals often require larger blades for adequate tissue depth, whereas delicate ophthalmic or pediatric work calls for finer blades. Safe scalpel handling, blade removal tools, and secure sharps disposal are critical to operator safety and infection control.

Blade choice affects incision quality and healing, and understanding blade mechanics naturally leads to comparing scissor types used for heavy versus delicate tissue work.

How do scissors like Mayo and Metzenbaum differ in veterinary applications?

Mayo scissors are robust with thick blades and blunt tips for cutting dense tissue and sutures, while Metzenbaum scissors have thinner shanks and fine, blunt or sharp tips suited for delicate dissection. Design differences—blade thickness, length-to-shank ratio, and tip geometry—determine leverage and precision; Mayo provides strength for fascial or muscular cuts, and Metzenbaum prioritizes reach and minimal tissue trauma when separating layers. In practice, Mayo scissors are favored for abdominal wall work and heavy tissue, whereas Metzenbaum scissors are the go-to for vascular or soft organ dissection. Regular inspection and correct sharpening preserve blade alignment and ensure consistent cutting performance across procedures.

These distinctions support correct tray assembly and instrument selection for specific clinical steps, preparing clinicians to match instruments to tissue type and surgical goals.

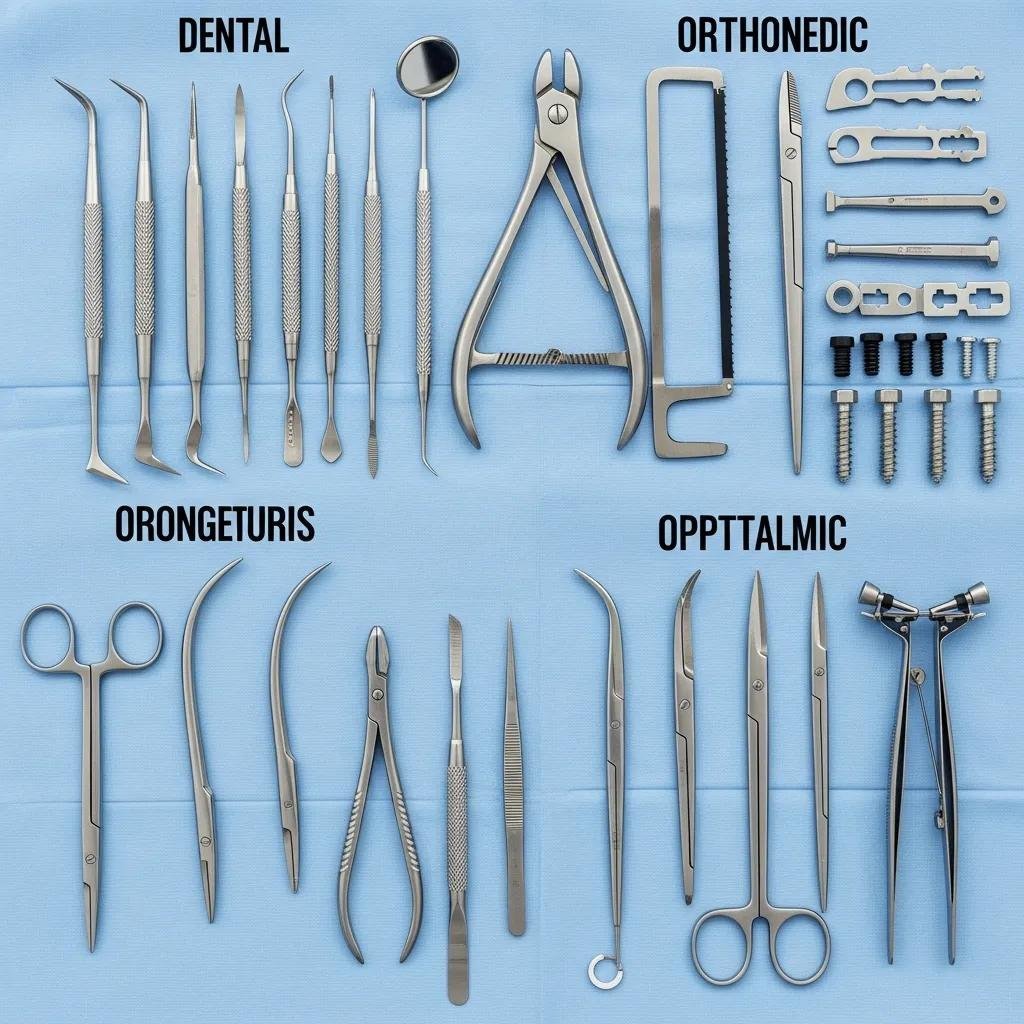

Which specialized veterinary surgical instruments are essential for dental, orthopedic, and ophthalmic procedures?

Specialty procedures require instruments tailored to anatomical and procedural demands: dental sets for oral mechanics, orthopedic kits for bone manipulation and fixation, and ophthalmic microsurgical tools for fine tissue work and magnified visualization. In dental practice, elevators, scalers, and mouth gags enable access and tooth extraction, with equine dentistry requiring floats and larger mouth gags. Orthopedic surgery uses bone cutters, osteotomes, rongeurs, and fixation instrument sets for fracture reduction and implant placement. Ophthalmic work depends on microsurgical scissors, Castroviejo needle holders, and fine forceps to manipulate delicate ocular tissues under magnification. Mapping specialty instruments to procedures ensures efficient case flow and reduces intraoperative instrument swaps.

| Instrument | Specialty | Typical Procedures / Uses |

|---|---|---|

| Elevators, extraction forceps | Dental (Small animal / Equine) | Tooth elevation, extraction; occlusal adjustment (floats in equine) |

| Dental scalers and probes | Dental | Periodontal debridement, diagnostic probing |

| Bone cutters, osteotomes, rongeurs | Orthopedic | Osteotomy, fracture debridement, shaping bone edges |

| External fixation sets, drill guides | Orthopedic | Fracture repair and implant placement |

| Castroviejo needle holders, iris scissors | Ophthalmic | Corneal suturing, eyelid repair, delicate ocular microsurgery |

| Microscopic forceps and micro-instruments | Ophthalmic | Fine tissue manipulation under magnification |

These mappings help clinicians assemble specialist trays and choose compatible instruments for anticipated procedures, reducing intraoperative delays and preserving instrument integrity. When matching instruments to specialty caseloads, practices benefit from suppliers that categorize offerings by specialty and animal type.

Vettrix Supplies lists specialized instrument categories—equine dental, orthopedic sets, and ophthalmic microsurgical tools—so practices can identify example kits and durable options aligned with these specialty requirements. Selecting instruments from catalogs organized by specialty helps streamline procurement and tray standardization while ensuring material quality and precision.

What are the common equine dental instruments and their uses?

Equine dental care relies on larger, robust tools: mouth gags to maintain oral access, elevators and luxation instruments for extraction, and floats or rasps for occlusal adjustments. Mouth gags must provide stable, adjustable opening while minimizing soft-tissue injury; elevators create leverage to loosen periodontal ligaments during extraction, and floats smooth sharp enamel points to restore occlusion. Safety considerations include patient restraint, sedation protocols, and protecting the operator from sudden head movement. Choosing corrosion-resistant materials and proper handle ergonomics reduces operator fatigue during longer equine procedures.

These equine-specific instrument needs tie into orthopedic considerations for larger animals, where bone force and instrument scale increase significantly.

How are orthopedic surgical tools like bone cutters and rongeurs utilized?

Orthopedic tools are engineered to withstand high forces and precise cutting; bone cutters and rongeurs mechanically remove or reshape bone during osteotomy, debridement, or implant site preparation. Bone-cutting saws provide linear cuts for osteotomies, while rongeurs bite away small segments of bone to contour edges or clear debris around fracture sites. Instrument selection depends on animal size and fracture type—larger animals require heavier-duty cutters and longer handles to achieve controlled leverage. Complementary instruments, including reduction forceps, elevators, and fixation sets, are combined in standardized orthopedic trays to enable efficient fracture repair.

Understanding these orthopedic mechanics informs sterilization and maintenance needs, since bone-cutting instruments are subject to heavy wear and require careful inspection and servicing.

How should veterinary surgical instruments be cared for, cleaned, and sterilized to ensure safety and durability?

Proper care follows a stepwise protocol: immediate pre-cleaning to remove gross contamination, ultrasonic or manual cleaning to eliminate residues, visual inspection and lubrication of joints, correct packaging, and validated sterilization cycles. Cleaning removes organic matter that can shield pathogens, while lubrication preserves ratchets and hinges; inspection identifies wear, pitting, or misalignment that necessitates repair or retirement. Packaging should protect instrument tips and maintain sterilant penetration; autoclaving remains the primary method for heat-stable stainless steel instruments, with chemical sterilants used when heat is contraindicated. Implementing a documented workflow with monitoring ensures patient safety and extends instrument life.

- Pre-clean: Remove gross debris immediately after use using disposable cloths and cold water rinse to prevent drying and corrosion.

- Clean: Use enzymatic detergents and ultrasonic cleaners or manual brushes to remove organic residue from hinges and serrations.

- Inspect and lubricate: Visually inspect for damage, test ratchets, and apply medical-grade instrument lubricant to joints.

- Package and sterilize: Place instruments in appropriate trays or wraps and run validated autoclave cycles or approved chemical sterilants as indicated.

- Document and monitor: Record sterilization parameters and use biological indicators regularly to validate cycles.

Following these steps consistently reduces infection risk and preserves instrument function, and selecting high-quality instruments further lowers maintenance burdens and replacement frequency.

Where to source quality instruments: Practices seeking durable, precision instruments may evaluate suppliers that emphasize material quality and a wide selection for various specialties. Vettrix Supplies positions itself as a provider of premium veterinary and surgical instruments, offering comprehensive catalogs organized by animal type and instrument type, with UVPs that include high-quality durable instruments, a wide selection for various specialties, commitment to precision, fast express delivery, 30-day returns, and secure payment processing. Choosing suppliers that prioritize durable materials and clear warranty or return policies supports long-term clinic efficiency and instrument reliability.

What are the recommended sterilization methods for veterinary surgical tools?

Autoclaving is the gold standard for sterilizing heat-stable surgical instruments, typically using saturated steam under pressure with validated cycles such as 121°C (250°F) for 15–30 minutes or 134°C (273°F) for shorter, higher-temperature cycles; cycle selection depends on packaging and instrument load. Chemical sterilants (e.g., peracetic acid or hydrogen peroxide-based systems) provide alternatives for heat-sensitive items, but clinics must adhere to contact time and concentration guidelines to ensure efficacy. Monitoring via biological indicators, chemical integrators, and routine maintenance of sterilization equipment confirms cycle performance and protects patient safety. Always follow manufacturer guidance for instrument materials, particularly for instruments with tungsten carbide inserts or delicate tips that may require specialized handling.

| Instrument Type | Recommended Cleaning | Sterilization Method & Parameters |

|---|---|---|

| Standard stainless steel (scalpels, scissors) | Enzymatic soak → ultrasonic/manual brush → inspect | Autoclave: 121°C for 15–30 min or 134°C short cycle depending on load |

| Hinged instruments (forceps, needle holders) | Pay special attention to ratchets and joints; ultrasonic cleaning recommended | Autoclave with lubricant on hinges; use pouch or cassette to protect tips |

| Instruments with tungsten carbide inserts | Clean carefully to avoid abrasive wear; inspect inserts | Autoclave per manufacturer; avoid prolonged exposure to high pH detergents |

| Heat-sensitive devices (certain optics or plastics) | Low-temperature compatible detergents; avoid autoclave if specified | Low-temperature chemical sterilant per validated cycle and contact time |

Adhering to these parameters and monitoring programs reduces sterilization failures and supports regulatory compliance, which in turn improves clinical outcomes and instrument longevity.

How can proper maintenance extend the lifespan of veterinary instruments?

Routine maintenance—daily cleaning, scheduled inspections, timely lubrication, and blade or insert sharpening—prevents premature wear and preserves function, reducing the total cost of ownership. Inspect instruments for pitting, corrosion, misaligned jaws, or dull blades; replace or repair components such as tungsten carbide inserts and sharpen cutting edges when performance deteriorates. Maintain a repair and retirement log to track instrument lifecycles and make procurement decisions based on usage patterns. Training staff on handling, transport in protective cassettes, and storage in low-humidity environments further minimizes damage and preserves sterile field integrity.

A consistent maintenance schedule integrated into the clinic workflow increases instrument reliability and reduces procedure delays, which supports better patient care and efficient resource allocation.

What factors should veterinary professionals consider when choosing surgical instruments for their practice?

Selecting instruments requires balancing procedure mix, animal sizes served, material quality, ergonomics, and budget to ensure safety and efficiency. Procedure frequency and specialty caseloads determine essential sets and backup quantities, while animal size influences instrument scale—equine and large-animal work demands heavier, longer instruments compared with small-animal kits. Material choices like corrosion-resistant stainless steel and tungsten carbide inserts for needle holders affect longevity and cutting performance, and ergonomic handle designs reduce surgeon fatigue during long cases. Budget planning should weigh upfront cost against expected lifespan and maintenance needs to optimize long-term value.

The checklist below helps procurement teams evaluate instruments against clinical needs and financial considerations.

- Assess procedural needs and specialty frequency to define core instrument sets.

- Match instrument scale to species and anticipated case complexity.

- Choose materials (stainless steel, tungsten carbide inserts) aligned with wear and sterilization expectations.

- Evaluate ergonomics, warranty, and supplier service to reduce downtime and operator fatigue.

How do procedure type and animal size influence instrument selection?

Procedure type dictates instrument function and quantity: soft-tissue surgeries require a robust set of cutting and suturing tools, while orthopedic cases need bone-specific instruments and fixation hardware. Animal size determines instrument dimension and force requirements—for instance, equine procedures use longer handles and stronger bone cutters, whereas feline surgery favors finer blades and delicate forceps. Mixed-practice clinics should maintain scaled instrument sets and consider modular kits to adapt to different species without excessive inventory. Anticipating common caseloads helps prioritize purchases and manage sterilization throughput efficiently.

Recognizing these scale and function relationships clarifies why material quality and ergonomics are critical to both performance and staff safety.

Why is material quality and ergonomics important in veterinary surgical tools?

High-grade stainless steel resists corrosion and deformation under repeated sterilization cycles, while tungsten carbide inserts extend jaw hardness and maintain grip on suture material; both materially driven choices reduce replacement frequency. Ergonomic handle designs distribute force more evenly, lower hand fatigue, and improve tactile feedback, which increases precision during lengthy procedures. Investing in quality materials and ergonomic design often results in lower total cost of ownership despite higher upfront costs, due to reduced maintenance, fewer instrument failures, and improved clinical outcomes. Practices should prioritize materials and ergonomics that match their caseload intensity and staff preferences to maximize value.

Material and ergonomic selection balances clinical performance with financial planning, supporting safer, more efficient surgeries and better long-term instrument resilience.

What are the latest trends and advancements in veterinary surgical equipment?

Contemporary trends in veterinary surgery emphasize minimally invasive techniques, electrosurgical integration, and digital toolchains that enhance precision and reduce recovery times. Minimally invasive surgery (MIS) — laparoscopy and endoscopy — uses specialized long instruments and ports to reduce incision size, with demonstrated benefits including faster recovery and lower postoperative pain. Electrosurgical devices enable controlled tissue cutting and coagulation, reducing blood loss when used with proper safety protocols. Digital integration—such as imaging, intraoperative video, and instrument tracking—improves documentation and decision-making during complex cases, and emerging smart instruments offer telemetry for usage and maintenance data.

These advancements reshape instrument procurement and training priorities, and understanding their operational implications helps clinics plan adoption and staff skill development.

How are minimally invasive and electrosurgical instruments changing veterinary surgery?

Minimally invasive instruments extend veterinary surgical capabilities by allowing procedures through small portals with cameras, reducing tissue trauma and shortening convalescence periods for patients. Electrosurgical units provide combined cutting and coagulation modes, enabling efficient hemostasis in procedures ranging from soft-tissue excisions to complex abdominal surgery. Adoption requires investment in compatible instruments, staff training, and new sterilization workflows for reusable MIS components. Benefits include quicker return to function and fewer wound complications, but clinics must weigh learning curves, capital costs, and case selection to implement MIS and electrosurgery safely and effectively.

As digital workflows advance, instrument telemetry and imaging integration further support safer, data-driven surgical practice.

What role does digital integration play in modern veterinary surgical tools?

Digital integration enhances precision through surgical imaging, intraoperative documentation, and instrument tracking that supports inventory management and maintenance scheduling. Image-guided procedures and high-definition endoscopy improve visualization and enable more precise resections, while electronic logs of instrument usage inform preventive maintenance and replacement planning. Emerging trends include instrument telemetry for lifecycle data and integration with practice management systems to streamline scheduling and supply replenishment. These innovations improve surgical outcomes and operational efficiency, encouraging practices to evaluate digital readiness alongside instrument acquisitions.

Adopting digital-enabled instruments and workflows supports long-term quality improvement and aligns instrument procurement with modern standards of care.

Add comment